Voltage interaction with thick clothing poses significant risks during stun device usage, leading to severe injuries. To mitigate these dangers, a robust Safety Lock Mechanism for Stunners is crucial, ensuring devices remain inactivation until intended use. Designing this mechanism requires balancing swift access needs against accidental discharge prevention, focusing on durability, sealing, and intuitive operation through clothing. Rigorous testing across various scenarios and adherence to electrical safety standards are vital for successful implementation.

Voltage penetration through thick clothing is a critical safety concern, especially in high-risk environments where electrical hazards are prevalent. This article delves into the science behind voltage behavior and its interaction with materials, focusing on the risks associated with high-voltage penetration of clothing. We explore essential design considerations for the Safety Lock Mechanism for Stunners, detailing implementation and testing protocols to ensure user safety. Understanding these factors is paramount in mitigating potential dangers.

- Understanding Voltage and Its Behavior Through Materials

- Risks Associated with High-Voltage Penetration of Clothing

- Design Considerations for a Safe Lock Mechanism

- Implementation and Testing Protocols for the Stunner's Safety Lock

Understanding Voltage and Its Behavior Through Materials

Voltage, a fundamental concept in electricity, represents the potential energy per unit charge, driving electric current through various materials. When it encounters different substances, its behavior changes significantly, especially when penetrating thick clothing. This phenomenon is crucial to understand for both safety and technical applications, including those involving stun devices with integrated Safety Lock Mechanisms.

The interaction between voltage and materials depends on their electrical properties like conductivity, permittivity, and dielectric strength. In the context of thick clothing, which is typically insulative, voltage tends to travel in straight lines, experiencing resistance and potential attenuation over distance. The depth of penetration is influenced by factors such as the fabric’s thickness, moisture content, and material composition. This knowledge is essential for designing safety mechanisms like those found in stunners, ensuring they function effectively while minimising the risk of electrical shock or unintended activation through clothing.

Risks Associated with High-Voltage Penetration of Clothing

The high-voltage penetration of clothing poses significant risks, especially when dealing with electrical equipment like stun guns that utilize powerful jolts. While these devices are designed to incapacitate individuals through electric shock, the impact on human tissue can vary dramatically based on voltage levels and clothing thickness. In extreme cases, high-voltage discharge through thick fabrics could lead to severe burns, internal damage, or even cardiac arrest.

Given these dangers, incorporating a robust safety lock mechanism for stunners is paramount. Such mechanisms ensure that the device remains inoperable until intended use, minimizing accidental activation and the subsequent risks associated with voltage penetration of clothing. This feature underscores the importance of prioritizing user safety, especially considering the unpredictable nature of situations where stun guns may be employed.

Design Considerations for a Safe Lock Mechanism

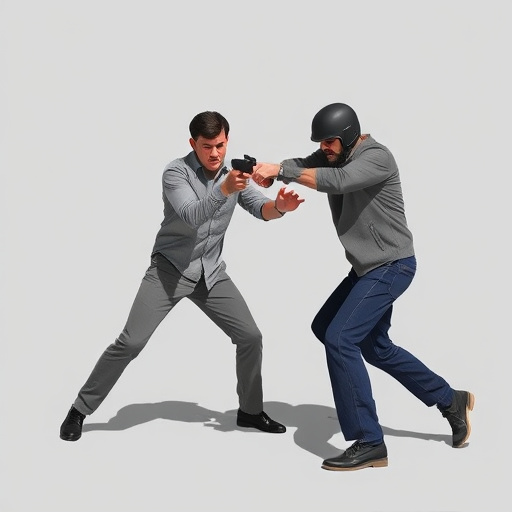

When designing a safety lock mechanism for stun guns, particularly those intended for use in situations where thick clothing is likely, several key considerations come into play to ensure both functionality and user safety. The primary goal is to create a secure locking system that prevents accidental discharge while allowing swift access when needed. This requires careful thought about the type of locking mechanism employed, its strength, and the overall build quality.

For instance, a robust and durable lock with a reliable sealing mechanism can prevent unwanted activation caused by movement or pressure from clothing. Additionally, an intuitive design that allows for easy operation under stress, even through thick fabric, is essential. Features like a quick-release lever or a sensitive pressure sensor that triggers the lock can significantly enhance safety and effectiveness in real-world scenarios where quick access might be crucial.

Implementation and Testing Protocols for the Stunner's Safety Lock

The implementation and testing protocols for the Safety Lock Mechanism for Stunners are paramount to ensure user safety during operation. The lock is designed to prevent accidental discharge, especially when stun guns are carried in pockets or holsters within thick clothing. Testing should encompass a range of scenarios mimicking real-world conditions: this includes evaluating the lock’s effectiveness against various fabric thicknesses and textures, as well as its responsiveness to different grip pressures.

Mechanical durability tests should be conducted to assess the lock’s longevity under repetitive use and potential stress from impacts or sudden movements. Additionally, electrical safety standards must be rigorously followed to guarantee that the lock doesn’t interfere with the stun gun’s functionality while ensuring user protection.

In conclusion, understanding how voltage behaves through various materials, especially thick clothing, is crucial for mitigating risks associated with high-voltage shocks. The article has highlighted the importance of a well-designed Safety Lock Mechanism for Stunners to prevent accidental penetration. By implementing robust design considerations and adhering to stringent testing protocols, it’s possible to ensure the safety of users without compromising functionality. These measures are essential in enhancing overall protection, especially in industries where high-voltage equipment is commonly used.